Acrylic solid surface

Acrylic stone, also called acrylic solid surface, is a mixture of natural stone elements and acrylic resin. About 2/3 of this homogeneous material is composed of crushed to dust natural stone mass and bauxite (aluminium ore composed of aluminium hydroxides, iron oxides, and silicon oxides), and 1/3 of acrylic resin (PMMA). The properties of acrylic solid surface are unique, and the colour palette is almost unlimited.

Neither bacteria, nor fungal spores can penetrate acrylic solid surface as it is non-porous. This makes solid surface worktops hygienic, and therefore desirable not only in kitchens and bathrooms, but also in restaurants, bars, medical institutions. They are loved for their beauty, durability, and easy maintenance. Acrylic solid surface can be used to create non-standard products of various designs and shapes, and suits well in private and public areas, both indoors and outdoors.

Acrylic solid surface fabricators in Lithuania

Advantages of acrylic solid surface

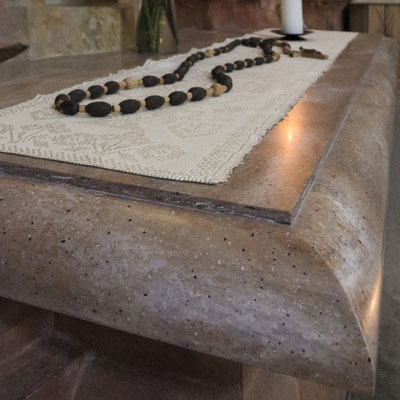

When acrylic solid surface slab is heated, it becomes flexible and can be folded it into any shape. This process, called thermoforming, takes place in a special furnace. By thermoforming acrylic stone, fabricators produce sinks of any size and shape, which are later integrated into acrylic countertops without visible seams. This is how curvy table legs, fancy rounded railings, round domes and elaborately shaped altars come about. The flexibility of acrylic stone makes it possible to fabricate elegant, lightweight furniture.

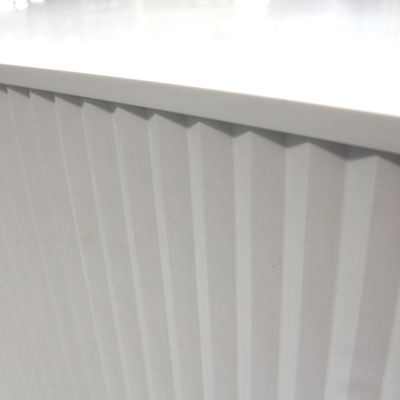

Acrylic solid surface countertops or any other items look one-piece because their joining seams are invisible. Whatever the size of the final piece, all its parts can be firmly joined together without the slightest gap in-between them. This not only contributes to a great look of the final item, but also simplifies its maintenance, as no room remains for the dust and dirt to accumulate.

Even very dirty acrylic stone worktops can be easily cleaned with simple dishwashing liquid and a sponge. Neither beetroot juice, nor red wine spilled on a white countertop is a problem. That's why acrylic worktops are appreciated in kitchens, bathrooms and public places, such as restaurants, hospitals, medical institutions.

Acrylic solid surfaces do not release chemical compounds into the environment, therefore items produced from this material can be used by people with allergies. Most acrylic stone brands have Green Guard Environmental Institute Certificate. This makes it desirable in medical institutions such as dental clinics or hospitals. Cinemas, theatres, airports are often equipped with sinks, counters, tables made of acrylic stone.

If acrylic stone countertop becomes scratched or dull, it can be polished again to make it look like new. What's more, damaged solid surface pieces can be easily repaired. After having your broken countertop repaired, you probably won't be able to trace the former faulty area even through a magnifying glass.

Because acrylic solid surfaces contain acrylic resin, they can be burned. Hot pans and pots, especially flat-bottomed ones, should not be placed directly on such worktops. This material can also be scratched with a sharp object, therefore cutting boards should be used when cutting products.

Acrylic solid surface suppliers

How acrylic solid surface is made

First, marble dust, some pigment and hard chips that give the final product its appearance are weighed and mixed according to the recipe. Then a liquid mass of acrylic polymers is added. All this mix is continuously poured between stainless steel sheets, which are slowly drawn into the steam oven. The width of the liquid surface is limited by spacers. Hot water is sprayed onto the sheets to start the polymerisation process. The acrylic mass is finally cured by passing through a long steam oven. When the continuous sheet comes out of the oven on the other side, it is cut into standard size sheets like a large piece of rolled out dough. These sheets are transferred to sanding machines and polished to bring out the surface pattern and make the sheet smooth.

What are acrylic solid surface properties?

- Long life

- Hygienic

- Resistant to stains

- Hard to put on fire

- Resistant to up to 80 °C heat

- Resistant to wear

- Resistant to UV rays

- Solid (finished product forms one piece)

- Non-porous

- Seams are invisible (final product looks like one piece)

- Easy to clean, to maintain, and to repair

- Non-toxic

- Hard

- Durable

- Lends to thermo-forming

- Some colours are translucent

- Relatively warm, pleasant touch

- No sealing required

What is acrylic solid surface used for?

Kitchen worktops

Bathroom vanities and bath tubs

Sinks

Shower trays, walls and capsules

Interior and exterior wall cladding

Furniture facades and doors

Swimming pools

SPA and wet rooms

Window sills

Reception desks

Bar tables

Restaurants

Food zones

Medical zones

How to clean solid surface worktops?

It is sufficient to clean acrylic stone worktops regularly with warm water and dishwashing liquid. This hi-tech material is non-porous, no mold or bacteria can penetrate into it. Acrylic solid surface does not need to be sealed. When cleaning acrylic worktops, abrasive pastes and brushes should be avoided. Certain cleaners and chemicals can damage and discolour acrylic surfaces. This particularly applies to drain cleaners, oven cleaners, paint strippers, solvents, acetone and nail polish removers.